-

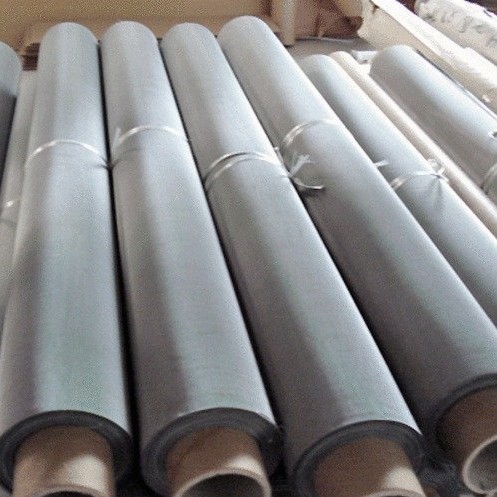

Selcuk Wire Industry

Selcuk Wire Industry Welcome to our website....

-

Corparate

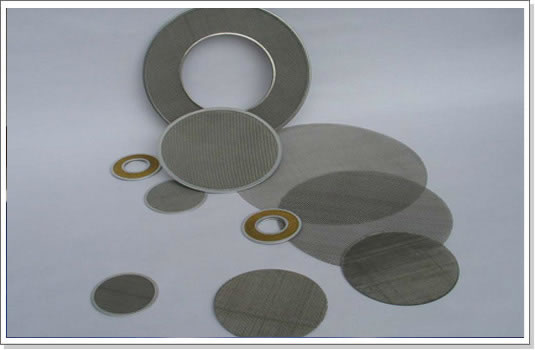

Our company was founded with the aim of procuding stainless mesh filter wires. Our company; has got a large market with the high quality production in Turkey market in a short time and it became to be required company in this area. Our company which imports stainless steel(chromium-nichel) wires in filter manufacturing too; has been leading institution in point of high quality, reasonable price, with the principle of timely delivery of raw materials.

Selçuk Tel Sanayi, which never comprise its quality, makes its all products according to the ISO 9001-2000 quality systeem, imports producers who have got this document and makes distributor.

Our company which answers any and all demands, needs and problems of our valuable customers; that's why; it has been a major name in this sector. Sizes and dimensions are produced according to the demands of our customers

Solution partner in production, Selçuk Tel Sanayi, presents a fair price which is needed and branded to all products groups and a reliable brand in the sipirit of its customers. It shows differences in determine your needs, promotion of use characteristics with feature to help. -

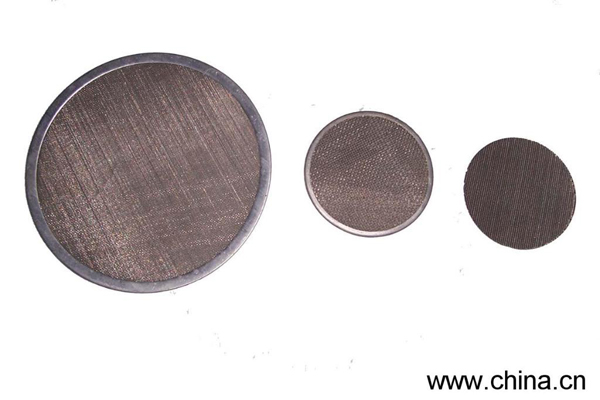

Band Filters

-

Double-Braided Rubosto Wire

TYPE OF MATERİAL

It is imported as AISI 304-304L-316-316L quality. It consists of phosphor bronze, brass and chrome nickel varieties.

Properties and Uses of Chrome Nickel Sieve Strands

Granite quartz ovens, food industry, fertilizer industry, automative industry, textile industry, pharmaceutical and chemical industries, plastic raw materials industry.KNİTTİNG PATTERNS

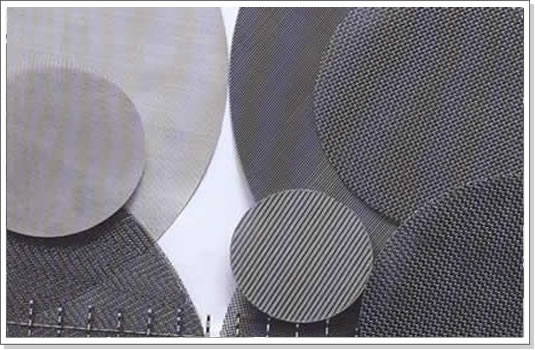

PLAIN WEAVE

It is a kind of weave which each horizontal and vertical weave pass a lattice from top and from second's under. This is the simplest and most widely used type of weave. Also it is named as square mesh too. This lattice will be eliminated and it provides a plus measure control for material to be filtered. Each of lattice passes at right angles from bottom and top. The amount of space between each lattice is the same.TWILLWEAVE

Techniqual İnformation:

It is a kind of lattice which passes an over and a gold of horizontal on vertical in the order. Horizontal meshes at weave create a parallel shape. Binary allows to the use of a heavier wire for the number of a specific pattern. It is stronger than plain weave. Applications, which are thin than 300 mesh typically, are two fabrics.Mesh

Tel Çapı mm

Delik Çapı mm

250

0.040

0.061

00

0.040

0.045

325

0.035

0.038

350

0.030

0.042

400

0.030

0.0335

450

0.028

0.028

500

0.025

0.026

PLAİN DUTCH WEAVE :

It is same structure with the dual flat-woven.But horizontal braids are more wide-spread. Horizontal and vertical lattices are approximated well to each other. Thus they form a line-shaped layout. While horizontal braids are staying plain in Dutch weave type, vertical braids shrivel up. Plain dutch weaving is used to be as a type of filter weaving too. Openings remain as diagonal slanted and unnoticed at first glance. Horizontal weaves of this lattice are more coarse, vertical weaves is thinner. Thus it creates more uniform and firm texture. Texture consists by weaved of vertical lattice with horizontal lattice. It is mostly used in high pressure filtration processes.MICRON TABLE Mesh

mm.

inç

micron

80 x 400

0.120 x 0.076

0.0047 x 0.0030

40 ~ 50

80 x 330

0.120 x 0.085

0.0047 x 0.0033

48 ~ 55

50 x 250

0.140 x 0.112

0.0055 x 0.0045

58 ~ 63

40 x 200

0.180 x 0.140

0.0070 x 0.0055

70 ~ 75

30 x 150

0.230 x 0.180

0.0090 x 0.0070

95 ~ 100

24 x 110

0.380 x 0.250

0.0150 x 0.0100

115 ~ 125

12 x 64

0.580 x 0.420

0.0230 x 0.0165

270 ~ 290

TWİLL DUTCH WEAVE:

It has similar to double weaving. But horizontal braids are greater than vertical braids and vertical lattices are weaved to touch each other. It creates a striped and shaped structure. Horizontal braids remain in a straight shape but vertical braids create a curve. Vertical texture shrinks both deeply and laterally becouse of dual woven. Bilateral Dutch Woven provides a stronger structure than normal Dutch woven. It can collect more wire in a certain area. Generallt; ıt is thinner knitted and less flow according to other Dutch fabrics and can eliminate even the 2 micron particles.

MICRON TABLE Mesh

mm.

inç

micron

635 x 4300

0.020 x 0.013

0.0008 x 0.0005

3 ~ 4

500 x 3500

0.025 x 0.015

0.0010 x 0.0006

5 ~ 6

400 x 3000

0.030 x 0.018

0.0012 x 0.0007

6 ~ 7

325 x 2400

0.035 x 0.024

0.0014 x 0.0010

8 ~ 9

270 x 2000

0.040 x 0.028

0.0016 x 0.0011

10 ~ 11

250 x 1600

0.055 x 0.037

0.0022 x 0.0015

11 ~ 12

200 x 1400

0.070 x 0.040

0.0028 x 0.0016

12 ~ 14

165 x 1400

0.070 x 0.040

0.0028 x 0.0016

16 ~ 18

120 x 1000

0.080 x 0.055

0.0032 x 0.0022

26 ~ 28

165 x 800

0.071 x 0.050

0.0028 x 0.0020

30 ~ 32

165 x 800

0.070 x 0.045

0.0028 x 0.0018

33 ~ 35

80 x 700

0.100 x 0.076

0.0040 x 0.0030

35 ~ 38

200 x 600

0.060 x 0.045

0.0024 x 0.0018

28 ~ 32

120 x 600

0.100 x 0.058

0.0040 x 0.0023

40 ~ 45

120 x 400

0.100 x 0.063

0.0040 x 0.0025

50 ~ 55

-

Rustless Sieve Wires

TECHNİCAL İNFORMATİON

Fabrics which woven with wire is used in many industries for the industrial requirements. Stainless steel produccts are 304-316 and 304 quality , And 304 quality products are available in our stock. 316 quality products is supplied according to special order. 304 quality wires are also known 18-8. It shows that percentage of 18% chromium, 8% nickel.

304 stainless is the main type of the steel. It provides a high oxidation resistance up to 450C. Its mechanical resistance and friction resistance are very good. Its application fields are chemistry, petro-chemical, food,kitchen, automotive, medical boiler and production of heat exchanger.

316 quality wires include extra 2% molybdenum. this material provides extra durable of wire against salt, acid and seawater. these wires are known as 18-10 too. 18% chromium,10% nickel. These wires provide high oxidation resistance up to 650C. Tensile and flexural strength is very good. Application fields are chemistry, petro-chemical, food, textile, paper indutry, But; because of the high corrosion resistance, they are mostly preferred in marine and industrial conditions.

AREAS OF USE

They are used in screening of all kinds of raw materials and supplies, also they are widely used as wire of filter and strainer. Especially they are commonly preferred because of withstanding high temperatures, they can be used very easily in water and acidic environments and becouse of superior mechanical properties.

Also;they are used in filter industry, granite and quartz mines, agriculture, industry, machinery industry, industrial kitchen industry, fertilizer industry, plastics industry, automative industry, textile industry, pharmaceutical and chemical industries you can see below in the table technical information of these wires sieve and filtration.

-

Contact

Address : Vatan Mahallesi Esenler Caddesi No:21/B Bayrampaşa / İSTANBUL Phone : +90 0212 544 68 02 Fax : +90 0212 544 68 02 Gsm : 0533 554 17 54 E-Mail : m.selcik@yahoo.com info@selcuktel.com pazarlama@selcuktel.com

View a larger Maps -

Areas Of Wire Usage

AISI FEATURES AREAS OF USE 304 It is the basic type of stainless steel. It is durable up to 450C. Its corrosion resistance and friction resistance is high because of nickel in it. Kitchen appliances, industrial kitchens, automative industry, food industry, chemical and petrochemical sector. 304 L It is AISI 304 and a kind of low carbon of steel, durable up to 500C. There is not frictional resistance. It has ability to take easy shape Chemical and petroleum industries dairy equipment, canning industry and aviation industry. 309 Because of their high rates of nickel and chromium, they provide oxidation resistance at temperatures up to 1050C. Furnace, burner parts and high heat- resistant equipment, chemical, petrochemical industry. 310 Its oxidation resistance is high at temperatures up to 1100-1200. Its amount of mekaniksek and corrosion strength is good. Furnace parts and high temperature resistant equipments, chemical and petrochemical industry. 316 It provides high corrosion resistance because of molybdenum in it. 600C heat-resistant. there are strength of mechanical tensile and shrinkage. Chemical and petrochemical industries, steam boilers, paint industry, fruit juice and beverage processing plants, pharmaceutical paint and varnish manufacturing facilities. 316 L It is a kind of 316 quality low-carbon.It has strength of temperature and okisdasyon. there is not frictional resistance above 500C. Chemical and petrochemical industry, paper industry, dairy equipment, artifical silk industry and the pharmaceutical industry. 316 Ti It is a kind which was added titanium of 316 quality. It has resistance of high temperature and okisdasyon. It is heat-resistant up to 650C Chemical and petrochemical industry, natural gas production units, pump and compressor parts, paper, chemical,pharmaceutical, paint and varnish manufacturing plants, and nuclear engineering industries. 321 It provides high resistance to have been stabilized corrosion by the addition of titanium. It is used at temperature between 450 and 800C. Resistance construction, exhaust pipes, breweries, canning industry and aviation industry. 409 It provides high temperature and corrosion resistance. The construction of the exhaust 430 It provides a good surface appearance, it can be magnetized becouse of not contain nickel. Thermal conductivity is more than 304 quality. Decorative uses, glossy surface applications, home appliances, automotive industry, the production of cutlery.